July Sustainable Business Champion - TGM Creative

This month our Sustainable Business Champion is TGM Creative, a family owned, local graphic design and marketing agency that recently celebrated 30 years in business.

They combine their love of great design with a growing passion for sustainability.

TGM Creative are going above and beyond to recognize ways to improve their service and their business practices. They take time to focus on each component of the printing process as well as understand every aspect of how and where products are sourced. Not to mention they are up-cycling banners into bags (see Andrea sporting one below).

The team at TGM hone in on the ins and out of printing – from the paper, to the ink, to the wastage of the printing cycle, as more and more of us want to be able to not only recycle but compost paper and card products at home.

Paper

As a major consumable in the print supply chain, paper is a prime sustainability focus.

As a matter of course, paper stocks are FSC or PEFC certified stock sourced from mills certified ISO 14001 in environmental management. The mill supplying uncoated paper is self-sufficient in water and power, with waste CO2 used in the paper whitening process. Pulp comes from farmed tree interspersed with other crops to maintain local biodiversity. The tree plantations are audited and certified by WMF (Well Managed Forests). The coated paper is produced without the use of elemental chlorine, so has virtually non-toxic emissions.

Printing process

The two main types of printing TGM offers is digital and offset.

Digital is like your personal inkjet printer on steroids – it doesn’t have any setup like offset printing and caters to small runs (no need to round up the print run to the nearest 500 or one thousand just in case) which means less paper wastage.

Offset printing requires transferring the image to plates, to a rubber blanket, then to the printing surface, and this not only uses ink but also requires ‘plates’ to be set up. TGM uses process-less plates called a ‘computer to plate system’ that does not require water or chemicals in the developing process because it is more energy efficient and uses less waste paper in the print setup. It is also very economical to print higher runs, so over estimating quantities can be the norm, which can lead to waste. Setup is also shared with other jobs to reduce waste – another great by-product of being part of a nationwide network.

The traditional printing process is a high energy, high chemical process, but TGM is part of a nationwide network that centralises their printing, which means they are able to continually invest and upgrade in the latest technology for the betterment of the environment (as well as to save their clients’ money).

The Inks

Isopropyl alcohol (IPA) is a major source of greenhouse gas emissions in the printing industry. TGM’s printing network uses the minimum amount of IPA in its printing processes, and we actively pursue technologies that will allow further reduction in the use of IPA.

The inks used in both of TGM’s systems are water based and contain less than 1% mineral oils. They are made from renewable sources. (Traditional printing inks are mineral solvent based.)

Reduce Reuse Recycle - and Compost

The team at TGM have also created satchels from old banners and signage, inspired by other organisations doing the same (see Andrea sporting one below).

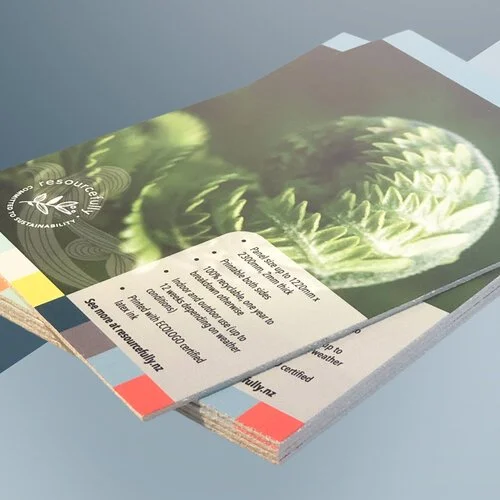

If you or your organisation are interested in reducing waste and making more sustainable choices through eco-friendly signage and packaging choices, please pay TGM Creative’s Resourcefully site a visit. For more fun inspiration, follow them on Instagram.